The bubble film produced by the bubble film bag making machine is a new type of plastic packaging material that is lightweight, highly transparent, non-toxic, and odorless. It can protect products against moisture, provide cushioning, and maintain temperature. The bubble film is extruded and thermoformed into bubbles at a high temperature of approximately 230°C, using high-pressure polyethylene as the main raw material, with the addition of auxiliary materials such as whitening agents and opening agents. It is a new type of plastic packaging material that is lightweight, highly transparent, non-toxic, and odorless, and can protect products against moisture, provide cushioning, and maintain temperature.

The stirring process in the bubble film bag making machine can partially convert into the surface free energy of concrete. The result of air entrainment leads to an increase in the free energy of the concrete system, making air-entrained concrete a thermodynamically unstable system. By adding different additives to the plastic raw materials, it is possible to manufacture various special-purpose air cushion films such as anti-static ones.

The stirring process of the bubble film bag making machine can be partially converted into the process of surface free energy of concrete. The result of air entrainment leads to an increase in the free energy of the concrete system, making air-entrained concrete a thermodynamically unstable system.

Since the middle layer of the air cushion film is filled with air, it is lightweight, transparent, and elastic, with sound insulation, shockproof, and wear-resistant properties. It is widely used for shockproof and cushioning packaging of electronics, instruments, ceramics, crafts, household appliances, bicycles, kitchenware, furniture, paint products, glass products, precision instruments, and other items. It can be made into bubble bags, bubble kraft paper envelopes, car sunshades, heat-insulating cushions, thermal insulation materials, etc.

By adding different additives to the plastic raw materials, various special-purpose air cushion films such as anti-static ones can be manufactured. The anti-static air cushion film is used for packaging electronic components and assemblies, such as boards and cards, which can prevent static electricity and play a role in cushioning and shockproofing.

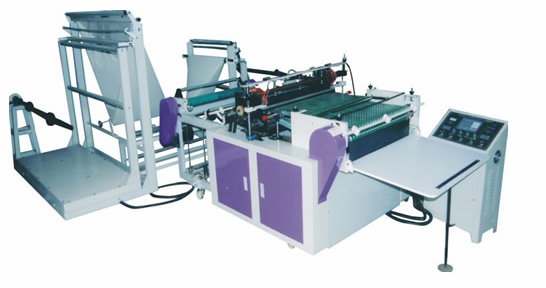

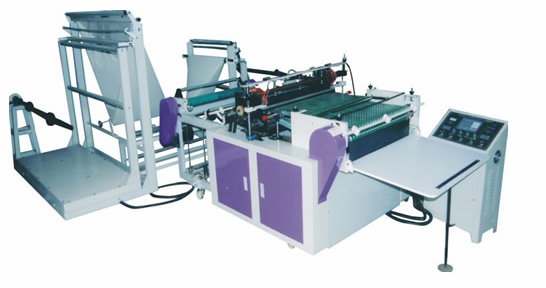

For more knowledge about bubble film bag making machines, please pay attention to Ruian Gaoxin Machinery Co., Ltd. ( http://www.ragxjx.com/), which specializes in the R&D and manufacturing of three-side sealing bag making machines, three-side sealing zipper stand-up bag making machines, and bubble film bag making machines. |